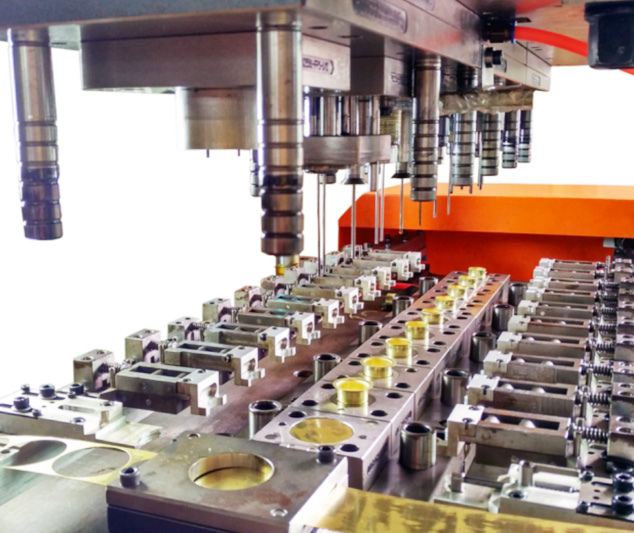

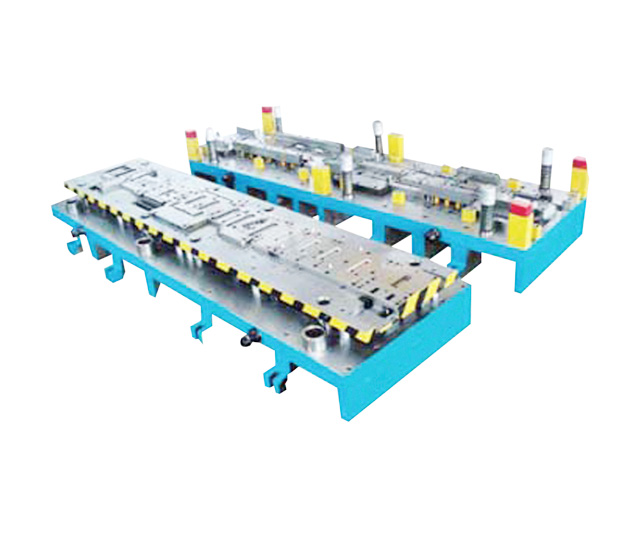

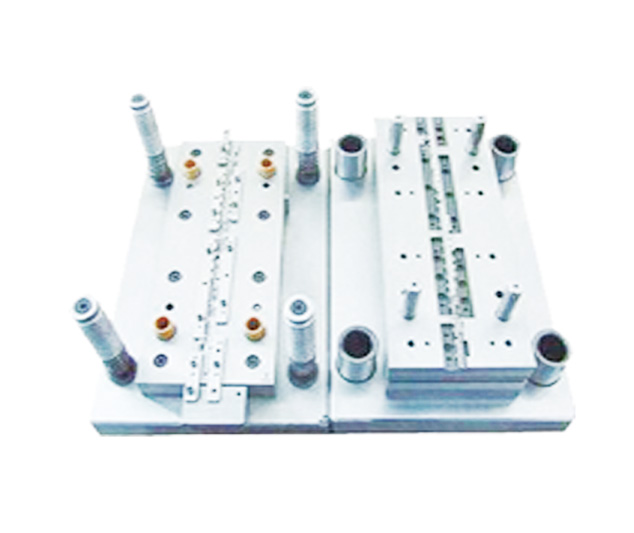

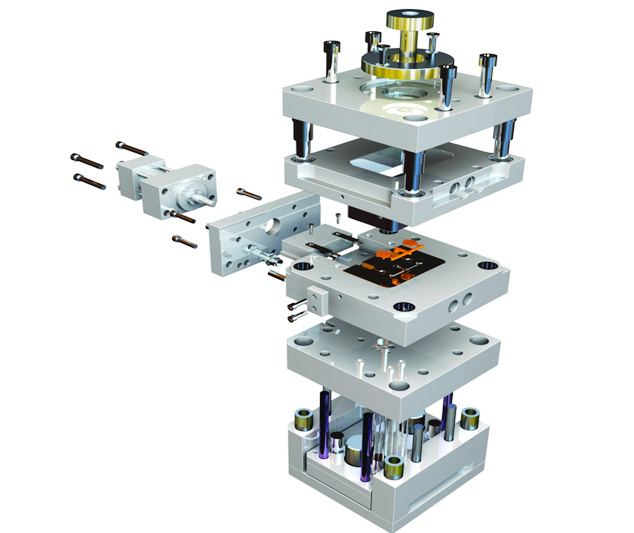

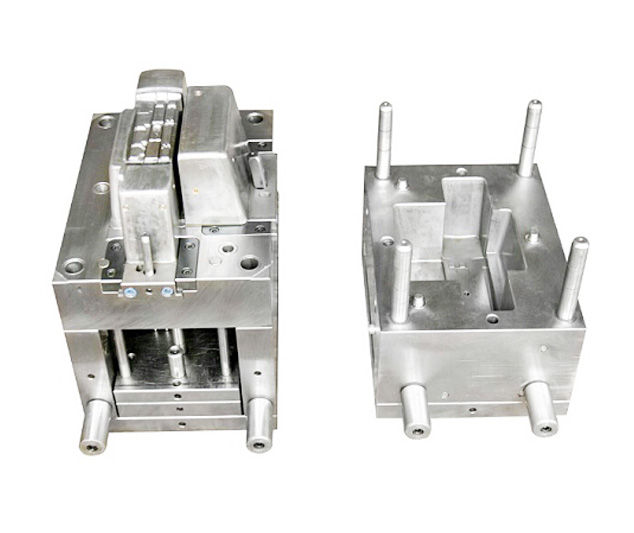

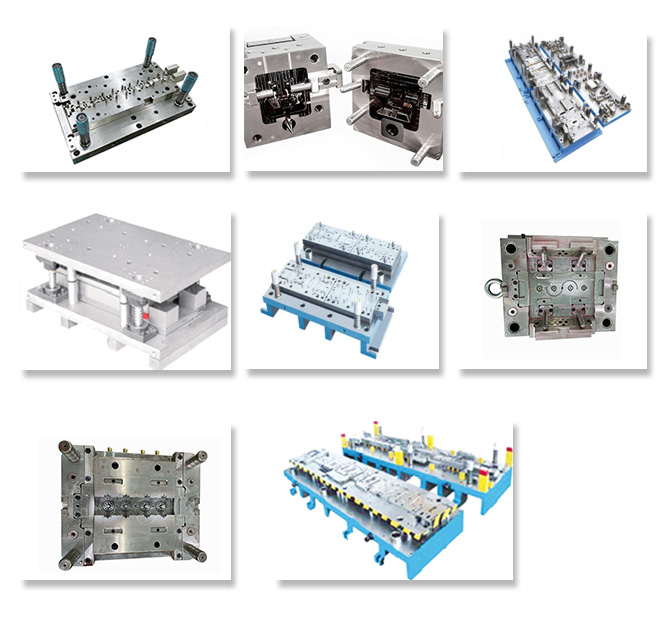

Precision metal progressive stamping die

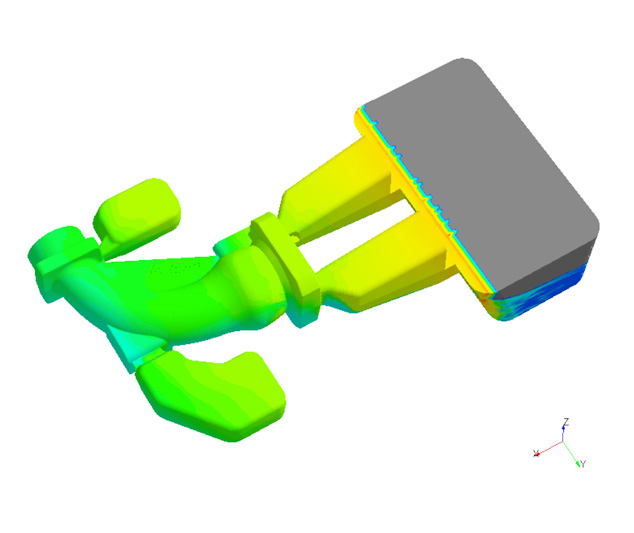

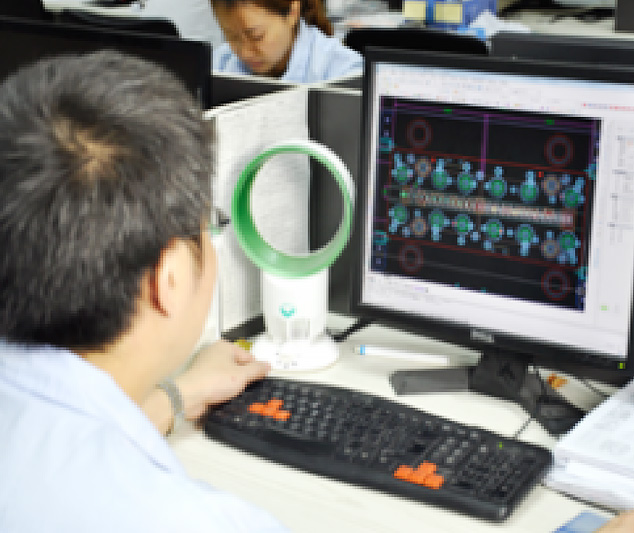

YALU group has strong mold technology development ability and

mold manufacturing ability.

Mold manufacturing has fast response, strong ability

and short cycle, and can be made according to different

technical requirements of customers,

Design and manufacture special molds for special products.

Mold development cycle:

One stage mould: 10-15 days;

two stage mould: 12-18 days;

Three stage mold: 15-25 days;

more than four stages: 20-35 days;

简体中文

简体中文