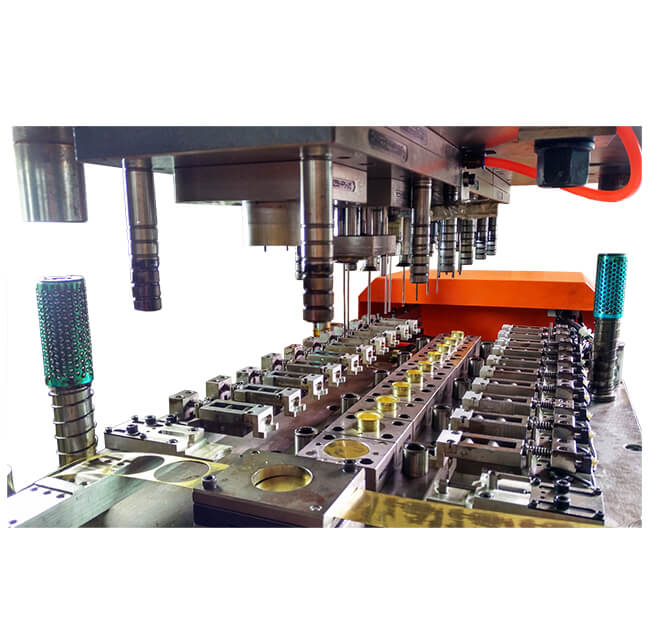

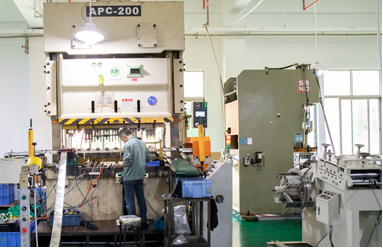

What is progressive drawing?

Progressive drawing is a method whereby coil or strip stock raw material is fed between an upper and lower die with multiple stations. With each stroke of the press, the material advances through the die – which has successive operations in each station to form one or more features of the part. A progressive drawing die may have anywhere between 2 and 20 or more stations to form a complete part.

简体中文

简体中文